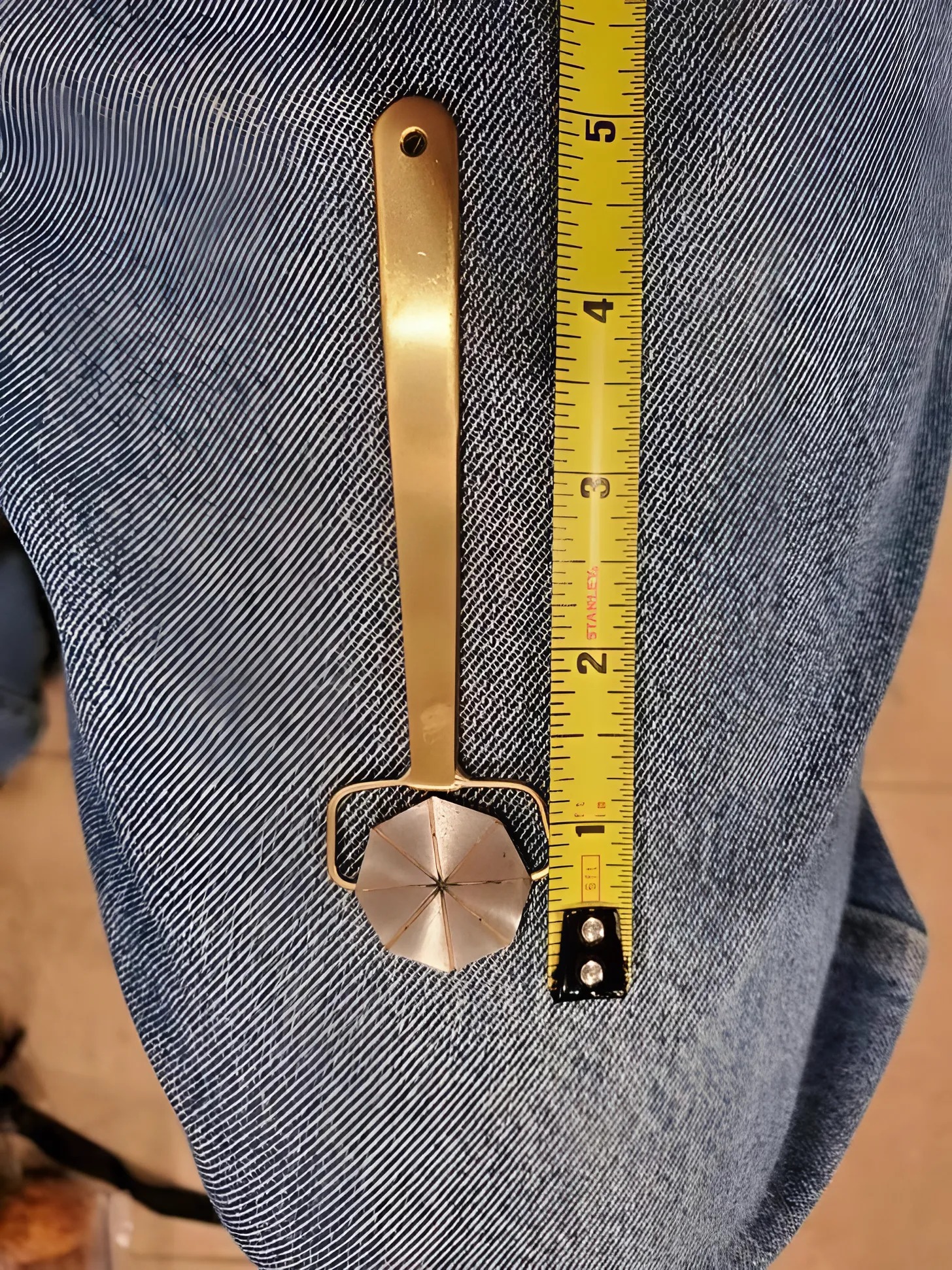

One ordinary afternoon at work, I wandered into an old storage room that hadn’t been touched in years, its shelves overflowing with dusty boxes, outdated parts, and forgotten tools. As I began exploring, opening drawers and inspecting anything that caught my eye, I stumbled upon something curious—a slim brass handle attached to a rotating octagonal head. The metal felt solid and cold in my hand, its design unlike anything I had ever seen before.

My first instinct was that it might be a specialized measuring tool, but no matter how I turned it over, I couldn’t figure out its purpose. The mystery gnawed at me, so I decided to dig deeper. What began as a quick search soon turned into an internet rabbit hole, scouring niche forums and flipping through scanned technical manuals from decades past. Eventually, I found my answer: this unassuming object was a magnetic field indicator, once an essential piece of equipment for railway workers. Suddenly, its design made perfect sense. The brass handle wasn’t just for aesthetics; it was non-magnetic and non-sparking, ensuring safety when working around delicate electrical systems.

The octagonal head, capable of smooth rotation, was designed to detect magnetic activity from multiple angles, allowing precise readings without missing any part of the field. In its prime, this tool was a quiet guardian of rail safety. It detected magnetic fields produced by electrical contacts along railway tracks—contacts that controlled signals, switches, and critical safety systems. If something went wrong, the readings from this device could pinpoint issues before they became dangerous, potentially preventing accidents and saving lives. I imagined a railway worker decades ago, standing by a stretch of track on a rainy day, holding this very tool and checking a connection.

That simple reading could mean the difference between a safe journey and disaster. The brass material wasn’t chosen just for corrosion resistance—it was also vital for preventing sparks in environments where electrical surges or fuel vapors could pose a risk. The rotating octagonal head allowed flexibility in measurement, ensuring no magnetic variation went undetected. Simple, durable, and efficient, it was the kind of tool designed to perform without fail, no matter the conditions.

Today, in an age of digital sensors and instant data, this might seem outdated, but back then it was state-of-the-art. It didn’t need batteries, didn’t malfunction in extreme weather, and could be trusted to work every single time. Its very existence was proof of the thoughtful engineering and meticulous craftsmanship that once went into even the smallest pieces of railway equipment. Holding it in my hands, I realized I wasn’t just looking at a tool; I was holding a piece of history. This device had no flashy buttons, no screens, and yet it had played an invisible but critical role in keeping trains running smoothly and passengers safe.

Instead of letting it sink back into obscurity in some forgotten drawer, I now keep it on my desk, not only as a fascinating conversation piece but as a reminder of the ingenuity and dedication behind the systems we take for granted. That day taught me something valuable—not every important tool announces itself with size, noise, or modern technology. Sometimes, the most unassuming objects carry a legacy of safety, precision, and trust. This brass-handled magnetic field indicator stands as a quiet testament to an era when even the simplest tools were built with the singular goal of protecting lives, proving that progress isn’t always about complexity—it’s about reliability.